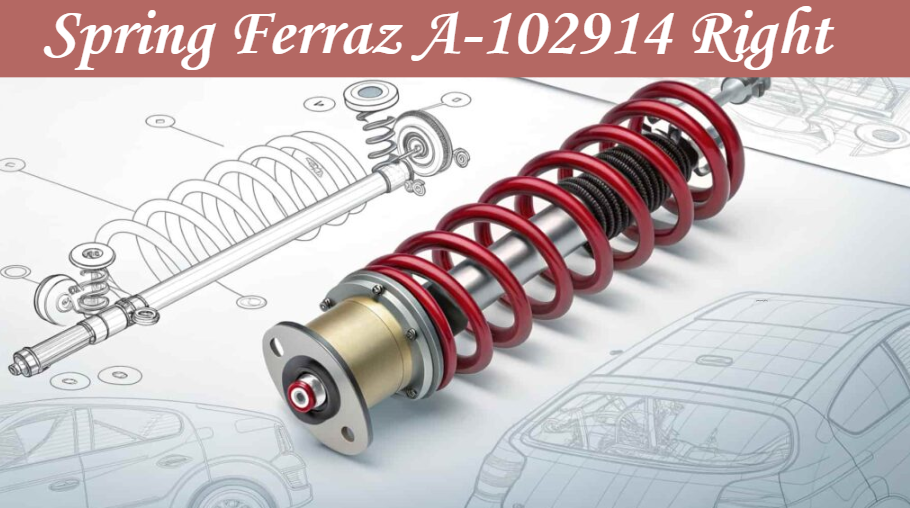

Spring Ferraz A-102914 Right: Complete Guide to Specifications, Uses & Maintenance

The Spring Ferraz A-102914 Right is more than just a mechanical component—it’s an essential part of modern machinery that plays a critical role in ensuring optimal performance, stability, and safety across numerous industries.

Whether you encounter it in automotive systems, aerospace engineering, or agricultural equipment, this spring exemplifies precision, resilience, and reliability. This guide is designed to explain everything you need to know about this spring in simple, easy-to-understand language, while remaining thorough and technically accurate.

Understanding the Spring Ferraz A-102914 Right

At its core, the Spring Ferraz A-102914 Right is a precision-engineered right-hand wound compression spring. A right-hand wound spring means the coils twist in a clockwise direction, which is critical for compatibility in systems that require specific rotation or assembly alignment.

This spring type is designed to absorb and store energy and then release it when necessary, helping to maintain pressure, absorb shock, or apply consistent force. What sets this particular model apart is its combination of high-grade material, robust construction, and adaptability in a wide range of operating environments.

Technical Specifications

Here’s a closer look at the core technical details of the Spring Ferraz A-102914 Right:

| Specification | Details |

|---|---|

| Model Number | A-102914 Right |

| Winding Direction | Right-hand |

| Material | High-tensile carbon steel / alloy steel |

| Surface Finish | Zinc plated / Oil coated / Powder coated |

| Load Capacity | Medium to high, application-dependent |

| Operating Temperature Range | -40°C to 150°C |

| Corrosion Resistance | Moderate to high (based on coating) |

| Diameter & Length | Varies by spec; custom sizes available |

These specifications ensure that the spring can perform consistently under different mechanical loads and environmental conditions.

Manufacturing Process

The Spring Ferraz A-102914 Right undergoes a multi-stage manufacturing process to ensure quality and durability. The process begins with the selection of high-tensile wire, followed by coiling on CNC machines that ensure precision in diameter and pitch. Once formed, the spring is heat-treated to enhance its strength and fatigue resistance.

Surface treatment is then applied to prevent corrosion and extend lifespan. The final step involves rigorous quality checks, including load testing and dimensional verification, to ensure each unit meets Ferraz’s high-performance standards.

Key Features and Benefits

This spring model boasts a number of features that make it ideal for demanding industrial applications:

- High Load Endurance – Engineered to handle heavy dynamic and static loads.

- Consistent Performance – Maintains shape and tension over repeated use.

- Material Versatility – Available in different materials and coatings for specific needs.

- Corrosion Resistance – Coated options available for outdoor or corrosive environments.

- Customizability – Can be manufactured in a variety of lengths, diameters, and strengths.

Applications Across Industries

The versatility of the Spring Ferraz A-102914 Right is evident in its wide adoption across industries:

Automotive Industry

In cars and trucks, this spring plays a critical role in suspension systems, transmission controls, and even fuel injection assemblies. Its shock-absorbing properties help improve ride quality and mechanical reliability.

Aerospace Engineering

Aerospace systems require parts that perform flawlessly under extreme conditions. The Spring Ferraz A-102914 Right is used in landing gear assemblies, flight control surfaces, and pressure regulation systems due to its high fatigue resistance.

Industrial Machinery

From CNC machines to conveyor systems, this spring is ideal for absorbing vibrations and maintaining tension. It helps in reducing mechanical wear, ensuring smoother operations, and minimizing downtime.

Agricultural Equipment

In rugged outdoor environments like farms, machinery relies on durable components. This spring helps in stabilizing systems in tractors, harvesters, and sprayers that operate over uneven terrain.

Renewable Energy

Wind turbines and solar panel tracking systems benefit from this spring due to its ability to maintain consistent pressure and alignment under load.

Medical and Electronic Devices

While smaller variants are used, the A-102914 Right finds a place in equipment requiring calibrated force such as infusion pumps, testing machines, and compact mechanical assemblies.

Installation Guidelines

Correct installation of the Spring Ferraz A-102914 Right ensures performance and longevity. Always identify the winding direction—this model is right-hand wound, which means it should be installed in clockwise-compatible setups.

Use the appropriate tools such as spring compressors or mounting brackets, depending on the application. Avoid stretching or compressing the spring beyond its designed limits, as this can reduce its working life or lead to mechanical failure.

Maintenance and Care

To keep the spring performing optimally:

- Inspect regularly for signs of fatigue, corrosion, or deformation.

- Clean using non-corrosive agents, especially in dusty or dirty environments.

- Apply lubrication if the spring operates in a high-friction or high-moisture area.

- Replace if you notice reduced elasticity or any visible surface wear.

Preventative maintenance not only extends the spring’s life but also protects the equipment it’s used in.

Common Issues and Troubleshooting

Here are some common issues that users may face with the Spring Ferraz A-102914 Right, along with possible solutions:

- Spring Fatigue – If the spring loses tension, it may be due to overuse. Replace with a new one.

- Rust or Corrosion – Often seen in outdoor applications. Use coated versions and apply anti-corrosion spray.

- Misalignment – Incorrect installation may cause the spring to twist or snap. Always ensure proper fit and orientation.

- Unusual Noise or Vibration – This could indicate that the spring is not absorbing load as it should. Inspection and possible replacement are advised.

Future Developments

Ferraz continues to innovate with new materials and precision engineering. Future versions of the A-102914 Right may include smart features like load sensors or be manufactured using composite materials for even greater durability and weight savings.

Additionally, 3D printing and AI-assisted design could make the spring more customizable, affordable, and efficient for niche applications.

Conclusion

The Spring Ferraz A-102914 Right stands as a testament to mechanical engineering excellence. Its combination of strength, precision, and versatility makes it an ideal solution for a wide array of mechanical systems. Whether you’re a designer, technician, or end-user, understanding the specifications and maintenance needs of this spring will ensure better performance and longer equipment lifespan.

By integrating this spring into your system, you’re investing in reliability and operational efficiency—qualities that define successful engineering solutions.

Recommended Articles

Valio Niketon: A Serene Residential Hub in the Heart of Dhaka

Ivanka Hrynda Stamford Address: A Luxurious Home Blending Modern Living with Community Spirit

Everything You Need to Know About the Survey at https://redcap.link/7ccgk1vm

lastlongerrightnow.com Wind Power Giants Leading the Renewable Revolution